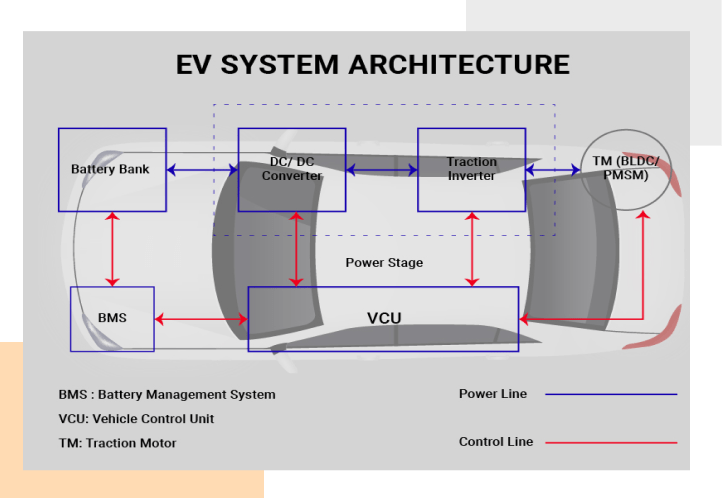

Traction Inverter And DC-DC Converter Solutions For Electric Vehicles

An electric vehicle’s primary propeller are traction inverters, which deliver torque and acceleration. The overall experience of driving an EV and customer satisfaction are intimately correlated with the reactivity of the inverter and the electric motor it regulates.

Ready-to-Deploy UDS Protocol Stack: Putting Vehicle Diagnostics in Fast Lane

Model Based Development (MBD) to give desire characteristics as per required customer data

Expertise in MATLAB simulation, Simscape tool for plant (EV) model

Supports MIL, SIL and HIL testing services

Reusable Models for customer convenience

Expertise in generation of SPWM, SVM, FOC algorithms

Selection of topologies as per requirement of customer data

Expertise in selection of Inverter rating as per customer specification / data

Supports all types of Motors (Induction Motor, BLDCM, PMSM, SRM)

Works as per ISO 26262 functional safety compliance

Schedule a quick call with our cloud experts and experience the best of cloud managed services.

Traction Inverter for EV

Embitel, with an industrial experience of over 15 years, provide

specialised traction inverter solutions to run the powertrains of

contemporary electric vehicles. Our demonstrated skill in creating

complex algorithms like FOC, guarantees a better functioning for your

Electric Vehicles.

Our team has successfully delivered

traction inverter solutions to electric vehicle projects all around

the world. We respond quickly to our client’s needs because we build

end-to-end inverter/converter solutions. So, if you want customized

traction inverter solutions, with the correct switching sequence and

FOC, you have come to the right place!

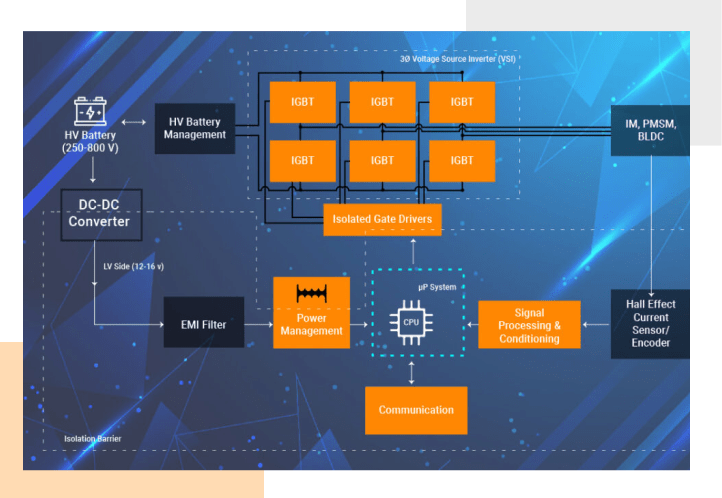

- High-power IGBT or SiC MOSFET power modules.

- High-voltage (HV) battery (48 V to 600 V)

- DC-link capacitor

- Sensing elements (Temperature sensor, Current Sensor, Voltage sensor, Position Sensor)

- Isolated Driver circuits

- Micro controller with power management IC

Technology Architecture of Traction Inverter for EV

Traction Inverter Solutions

- Power levels up to 30 kW and above, these systems require extremely robust IGBT and silicon carbide (SiC) components.

- 48-volt to 600-volt batteries supply power to traction inverters, requiring inverter components to be rated from 120 volts to 750 volts while operating at current levels up to 500 A per phase.

- A full ecosystem of parts to support wide bandgap power designs, including SiC diodes, SiC MOSFETs, and SiC Modules.

- MOSFET for Traction Automotive

- IGBT for traction Automotive

- SiC Modules for Traction Automotive

- Sinusoidal Pulse width Modulation (SPWM), Space Vector Pulse width modulation (SVPWM) control technique developed as per the application of inverter.

- Field Oriented Control (FOC) Algorithms:

- flux weakening for wider speed operation of traction drive.

- PI control with anti-windup, torque mode and speed mode.

- Space vector modulation.

- Provides the plant based MBD as per the customer Requirement.

- Expected converter efficiency is more than 90%.

- Maximum Regulation of less than 5% selected for load and line regulation.

- Isolation circuits solution provides to prevent damage to components during fault if required.

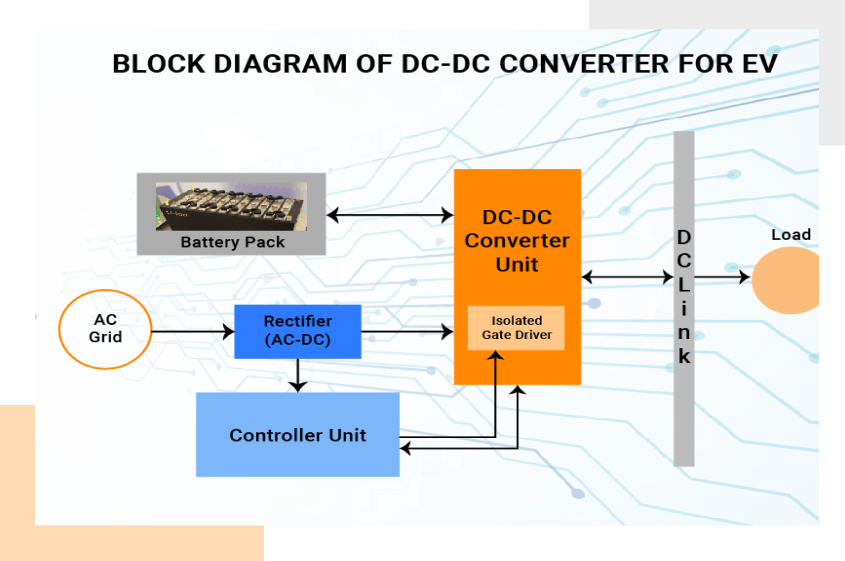

DC-DC Converter

OBD2 protocol software is at the core of an automotive ECUs’ built-in self-diagnostic system. It enables diagnostics-based communication with the ECUs such as Engine control unit, transmission control unit, electronic brake modules and more to detect and control ECU failures.

- High-power IGBT or SiC MOSFET power modules.

- High-voltage (HV) battery (DC Link) (48 V to 600 V)

- Inductor (High / Low frequency type)

- Power Diode

- DC-link capacitor

- Sensing elements (Temperature sensor, Current Sensor, Voltage sensor)

- Isolate Driver circuits for switching.

- Micro controller with power management IC

DC-DC Converter Solutions

- Power levels up to 30 kW and above, these systems require extremely robust IGBT and silicon carbide (SiC) components.

- 48-volt to 600-volt batteries supply power to traction inverters, requiring inverter components to be rated from 120 volts to 750 volts while operating at current levels up to 500 A per phase.

- A full ecosystem of parts to support wide bandgap power designs, including SiC diodes, SiC MOSFETs, and SiC Modules.

- MOSFET for Traction Automotive

- IGBT for traction Automotive

- SiC Modules for Traction Automotive

- Pulse width Modulation (PWM), control technique developed as per the application of Converter.

- As per the power devices (switches), switching frequency has been defined.

- Provides the plant based MBD as per the customer Requirement.

- Expected converter efficiency is more than 90%.

- Maximum Regulation of less than 5% selected for load and line regulation.

- Isolation circuits solution provides to prevent damage to components during fault if required.